Essential Details

Taizhou Xiangrong Precision Technology Co.Ltd.is located in Zhejiang Huangyan Mold in telligent town. whichis known asthehometown ofmold Our sales and service center is located in No.625 Gongxin AvenueNorth City ofHuangyanthe central location of Zhejlang coastal industrialEconomiczonenorth to Ningbo,south to Wenzhou207 km away from Hangzhou. We mainly produce hieh-end steel castines CNCbladesStainless steel NC bladetitanium alloy NO blade,superalloysteel casting NCbladestain less steel NCbladeTitaniumalloy CNCturning blade and other cost-effectve cuttine tools Our company is committed to hieh hard materials.stainless steel materials. titanium alloy materi alshigh-temperature alloy materials and other difficult to process materials,So to support the research and development of cuttingtools provides enterprises with high-quality cutting tools and helps enterprises solve practical problems.| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||

| ØI.C | S | d | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | ||

| RCKT10T3MO | 10 | 3.97 | 4.4 | ★ | ★ | ||||||

| RCKT1204MO | 12 | 4.76 | 4.4 | ★ | ★ | ||||||

| RCKT1606MO | 16 | 6.35 | 5.56 | ★ | |||||||

| RCKT2006MO | 20 | 6.35 | 6.55 | ★ | |||||||

| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||||

| | L | W | S | d | r | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | |

| APMT1135PDER-M2 | 11.4 | 6.2 | 3.65 | 2.8 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-M2 | 17.26 | 9.24 | 4.76 | 4.4 | 0.5 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1135PDER-H2 | 11.4 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-H2 | 17.25 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

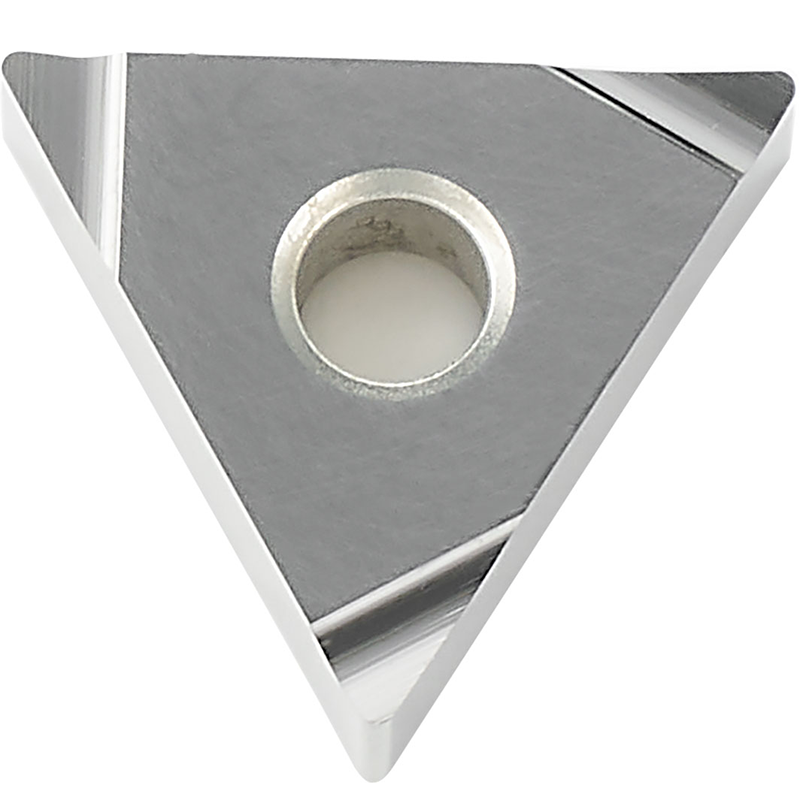

Product description

Product Packaging

Q1: Why should we buy from you not other suppliers? A1:XR cutting tools have 30% longer tool life in general, but much more competitive price, comparing to some Japanese famous brand. Q2:How can you guarantee quality? A2:Always a pre-production sample before mass production; Always final Inspection before shipment.RCKT10T3MO, RCKT1204MO, RCKT1606MO, RCKT2006MO are common blade models used in metal cutting. These inserts are manufactured from high quality materials to provide excellent cutting performance and long life. RCKT10T3MO inserts are smaller in size for tasks that require high precision and detailed cutting. It uses advanced edge geometry and premium coating technology to provide excellent cut quality and surface finish. This insert is particularly suitable for machining processes that require high accuracy and high surface quality, such as in the aerospace sector. The RCKT1204MO insert is suitable for medium cutting tasks, its size is moderate and its wear resistance is good. The insert features a solid edge geometry and a special tool coating that provides consistent performance during high-speed cutting. It is widely used in rough cutting and fine cutting of metal materials such as steel, cast iron and stainless steel, and is also suitable for light-duty cutting processes. The RCKT1606MO insert is a size between medium and large, suitable for a wide range of cutting tasks. It has good edge stiffness and head strength to handle high-speed and powerful cutting requirements. It is suitable for medium and rough machining of various metal materials, such as titanium alloy, aluminum alloy and alloy steel, etc. The RCKT2006MO insert is a large insert, suitable for high load and heavy cutting process. It has strong cutting ability and wear resistance, and can cope with high-speed and heavy-duty cutting requirements. It is widely used in heavy cutting tasks of steel, alloy and high hardness materials, such as automobile manufacturing and heavy machinery manufacturing. To sum up, RCKT10T3MO, RCKT1204MO, RCKT1606MO, RCKT2006MO inserts have different size and performance characteristics, suitable for different types of cutting tasks. Whether for fine machining or rough cutting, these inserts offer advantages in terms of wear resistance, cutting performance and cutting quality to meet a variety of machining needs.FAQs