Essential Details

Taizhou Xiangrong Precision Technology Co.Ltd.is located in Zhejiang Huangyan Mold in telligent town. whichis known asthehometown ofmold Our sales and service center is located in No.625 Gongxin AvenueNorth City ofHuangyanthe central location of Zhejlang coastal industrialEconomiczonenorth to Ningbo,south to Wenzhou207 km away from Hangzhou. We mainly produce hieh-end steel castines CNCbladesStainless steel NC bladetitanium alloy NO blade,superalloysteel casting NCbladestain less steel NCbladeTitaniumalloy CNCturning blade and other cost-effectve cuttine tools Our company is committed to hieh hard materials.stainless steel materials. titanium alloy materi alshigh-temperature alloy materials and other difficult to process materials,So to support the research and development of cuttingtools provides enterprises with high-quality cutting tools and helps enterprises solve practical problems.| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||||

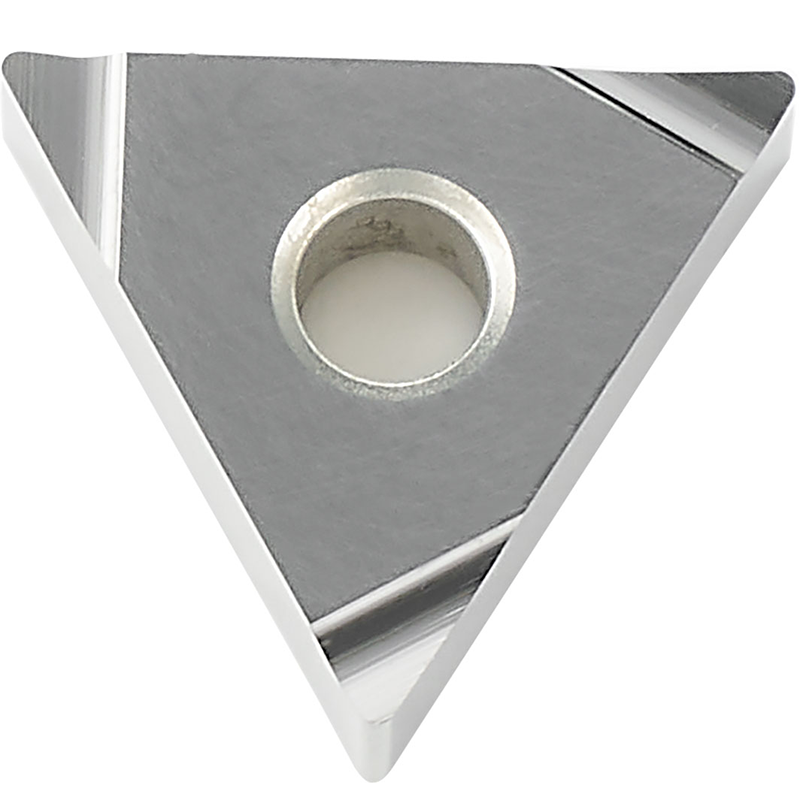

| WPGT080615ZSR | ØI.C | r | S | Ød | a | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | |

| 12.85 | 1.5 | 6.35 | 5.5 | 11° | ★ | ||||||||

| Blade Shape | Item No. | Item Size(mm) | Coated Carbide | ||||||||||

| | L | W | S | d | r | XS2011 | MP2011 | JP6001 | PY8001 | SP6608 | GY8808 | WG01 | |

| APMT1135PDER-M2 | 11.4 | 6.2 | 3.65 | 2.8 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-M2 | 17.26 | 9.24 | 4.76 | 4.4 | 0.5 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1135PDER-H2 | 11.4 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

| APMT1604PDER-H2 | 17.25 | 9.52 | 4.76 | 4.4 | 0.8 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |

Product description

Product Packaging

1. Are you manufacturer or trading company ? We are Professional manufacturer , located in Taizhou 2. What machine you use? You can see Walter& ANCA grinding machines in our factory, also have Zoller detection machine from Germany. 3. Is free shipping possible? We don't offer free shipping service, but we will give you some discount if you buy large qty products. 4. Can you send products to our Forwarder in China? Yes, if you have forwarder in China, i will glad to send products to him/her. 5. Do you make OEM? Yes, we do. We have laser machine, can laser your logo and sizes on the body of milling cutter, also can print labels. 6. How about the delivery time? According to the sizes and quantity, delivery time is different. Usually 3~7 days.We can tell you exact inventory state if you need.WPGT080615ZSR insert is a high-performance metal cutting insert, especially suitable for machining hard metal materials such as tungsten alloy, cast iron, stainless steel and steel. Using high-quality materials and advanced processing technology, this blade has excellent cutting performance and wear resistance. The WPGT080615ZSR insert adopts an advanced edge geometry design, which enables it to cut metal materials quickly and efficiently. The edge angle and edge curvature of the inserts are carefully designed to reduce cutting forces and improve cutting quality. At the same time, the blade also adopts professional coating technology to provide extra lubrication and protection, thus prolonging the service life of the blade. The WPGT080615ZSR insert is well sized for a wide variety of fine and rough machining tasks. Its blade is thinner, which can generate less cutting force, reduce cutting vibration and cutting heat, so as to obtain higher cutting efficiency and better processing quality. The inserts are suitable for a variety of cutting operations, including turning, milling and drilling, and for workpieces of different shapes and sizes. In addition to its excellent cutting performance, the WPGT080615ZSR insert also has the advantage of being easy to replace and adjust. Users can easily change the blade and adjust the tool to suit different processing needs. This insert also has good stability and reliability, and can maintain stable performance in high-speed and heavy-duty cutting environments. Overall, the WPGT080615ZSR insert is a high-quality, high-performance metal cutting insert that provides users with a reliable and efficient machining solution. Its cutting performance, wear resistance and adaptability make it widely used in various metal processing fields, and is favored by professional processing personnel and manufacturers. Whether it is fine machining or rough cutting, WPGT080615ZSR inserts can meet your needs and help you achieve high-quality machining results.FAQs